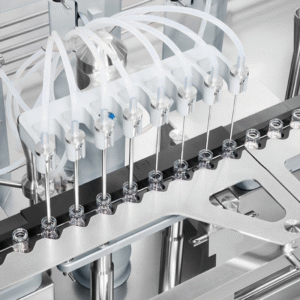

| Filling accurary | +/-1% |

|---|---|

| Dimension | 1500*2500*1250mm |

| Filling pump | Ceramic pump |

| Filling nozzle | 8pcs |

| Filling volume | 1-20ml |

| Material | Stainless Steel 304/ 316L |

| Power-supply | 380V 50Hz |

| Weight | 1800kg |

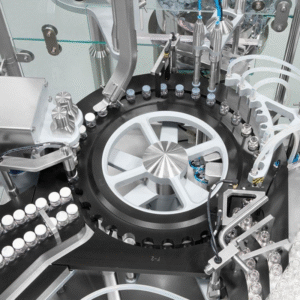

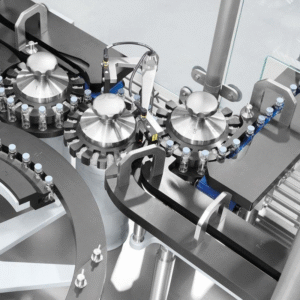

The Vial Liquid Washing Sterilization Aseptic Filling Stoppering Closing Machine, which consists of a Vertical Ultrasonic Vial Washing Machine, a Depyrogenation Tunnel, a Aseptic Filling and Stoppering Machine, and Capping machine, is suitable for the filling of 2ml -20ml vials. They can work as stand-along equipments and complete linkage lines.

Vial Loading ⇒ Ultrasonic Washing ⇒ Fine Washing (3 times of water washing and 3 times of compressed air washing) ⇒ Depyrogenation Sterilization ⇒ Pre-nitrogen Filling ⇒ Liquid Filling ⇒ Post-nitrogen Filling ⇒ Stoppering (Half Stoppering for Freeze Drying) ⇒ Capping ⇒ Vial Discharge ⇒ Labelling ⇒ Inspection ⇒ Packing

We will contact you within 1 working day, please pay attention to the email with the suffix “@sanzmachine.com”.